FREE UK DELIVERY ON ORDERS OVER £25

Help & Advice From our Service Engineers

This is a collection of great tried & tested tips, tricks, guides & "how to" advice from our Service Engineers & Customers. This section will keep growing, so keep an eye on it!

Free Support

We understand that it can be frustrating when your beloved air rifle isn't working as it should - whether you need it for work or for play. We spend a lot of time offering free support - and are happy to do so - if you want to send us £1 (or whatever, it's entirely up to you) to say "thankyou" we are always most grateful...

Servicing your HW100

It can be quite daunting the first time you attempt to service the HW100 yourself. Some of the most common mistakes people make are overtightening the gun when putting it back together, using the wrong tools or o-rings/seals or scratching the gun whilst trying to remove old orings. PLEASE be careful - the HW100 is a precision instrument. If you don't have the right tools or the confidence to attempt it yourself, please contact us or your local Gunsmith to do it for you.

Learn More

One of our customers, Martin Healy has made a series of 3 You Tube videos on how to service your HW100. MANY of our customers have found them helpful...

reducing weight

We are often asked how to reduce the weight of the HW100 rifle. We have the CS500 Sporter Skeleton Stock (made by Custom Stocks) on our HW100 rifles, this takes quite a bit of weight out of the stock and you can customise it on their website too. There is also quite a bit of weight in the standard rifle barrel - the FSB rifle barrel is thinner & lighter. Finally, our titanium air tubes are 45% lighter than the original steel tube - you just need to remove the end caps from your original Weihrauch air cylinder and screw them onto the titanium tube. If you have the FSB, this means you have room for a longer air tube too, which means it's lighter AND more shots.

CHRONOGRAPHS

Get yourself a chronograph. Anyone with an air weapon should own or have access to a chronograph and regularly test the power output to ensure that the gun is within legal limits (if your country HAS legal limits). It can also tell you if your gun is UNDER powered and needs a service, repair or just a barrel clean! ("Leading up" a barrel does not apply to PCPs - clean your barrel, you may find that the power goes up by half ft lb!)

Orings on your fill probe & Dust Plug - important!

We are seeing a lot of air cylinders coming to us for service because users are not putting lubricant on their fill probe & dust plug when they are filling their air cylinder. Dry bits of rubber are shearing off the probe & getting blown into the fill valve - debris in the fill valve will cause a slow or fast leak & can also stop you from filling the cylinder with air eventually. If you look in the Weihrauch User Manual, it will tell you never to oil your threads, valves or charging equipment for the air cylinder as there is a danger of explosion. This is because a lot of people don't realise that you can't just put ANY old oil or grease on your PCP - it has to be a VERY specific type of oil/grease - it has to be inert (chemically inactive) & therefore not dangerous to use on the fill probe. ALL rubber oring seals work better with a little bit of grease/oil on them - including the fill probe! See below for which oils/grease are safe. PLEASE, make sure your fill probe & dust plug are clean. Any bits of muck on your fill probe/dust plug are going to get blown into your fill valve.

Oils, Lubricants and Grease

NEVER put WD40 on your gun!

Only special lubricants/oil/grease specifically designed for pcp-air guns should be used. These are sophisticated oils specially formulated for this purpose. Of the hundreds of oils available, only a few have the proper viscosity, lubricity, lack of acids for use in fine quality pcp-air guns. Our workshop recommend Molykote 33M or our own Professional Airgun Lube - it is perfectly inert (chemically inactive) silicone based and perfectly safe to use on your PCP - even on the fill probe seals.

Never oil the connecting threads and valves of your rifle’s air cylinder and always protect the thread and inlet valve with the dust cover cap provided. That goes for the original Weihrauch cylinder AND our Titanium Cylinders. ALWAYS lube your fill probe with a silicone based oil/grease - otherwise dry bits of rubber from your probe can shear off and get caught in your fill valve as mentioned above.

FILLING/CHARGING YOUR PCP WITH A DIVE BOTTLE

Make sure that you are pushing the fill probe all of the way in, if you don't and one of the rubber oring seals on the probe is sitting on or catching the edge of the fill port/hole when you are filling (rather than a seal either side, well clear of the port), the pressure from the dive bottle might be shearing off bits of rubber seal and forcing them into the valve on your cylinder - this can cause your air cylinder to leak or it can stop air from getting INTO your cylinder. If this happens, you will need to unscrew the end cap off the cylinder (make sure the air cylinder is empty first), remove the valve and clean the rubber bits out - if you cannot do this yourself, you can send the cylinder to us for a service (£20 + return postage).

This is how to fill properly:-

(1) Put a bit of silicone oil/grease on the fill probe and seals

(2) Insert probe fully - keep your hand on the probe to make sure it stays in place

(3) Open the valve on your dive bottle to fill the gun

(4) Fill to required level - always go by the gauge on your dive bottle, not the gauge on the gun. The small gauges on the guns are notoriously inaccurate. The guages on dive bottles are usually of a much higher quality.

(5) Shut the valve off on the dive bottle (don't do this slowly as shown on some youtube videos, your valve will not shut off properly and you will lose air, do it fast - you get a nice SNAP and the valve closes, no loss of air)

(6) Release the flex/whip pressure using the dive bottle pressure release valve or screw

(7) Remove the probe from gun straight away.

Your pressure gauge will indicate a drop of 5 to 10 bar as the temperature changes over the next hour or so - this is normal.

Learn More

This is a good, no nonsense video on how to fill your PCP from a dive bottle by theairguncentre

Fill the Air Cylinder From a Dive Bottle or Pump?

Weihrauch recommend that you use "Divers air quality only" to fill your air cylinder - this is because it has a VERY small moisture content - you can only get this quality air from a dive bottle. Most Hills type pumps can only guarantee to provide air that is 90% moisture free - even with a dry pack filter attached. The picture here shows the fill valve from an air cylinder we serviced recently which has been damaged by prolonged exposure to moisture from using an air pump - we can't say whether the pump is damaged or how long it took for this damage to occur, but if you can, we would always recommend that you use a dive bottle. The damage on this particular fill valve pictured included the spring, seal and the valve housing - they were all covered in limescale/calcium from the excess moisture - the cylinder was leaking because the seal & housing was damaged and didn't have a flat surface to seal against due to the limescale build up.

Any time that you fill your cylinder from empty, remove it from the gun to fill with air 150 to 200bar, then screw it back onto your gun. This is so that the exhaust valve gets a good shot of air to create the best seal. You should do this anytime that your air cylinder has completely emptied to avoid leaks…

WHY IS MY GUN FIRING ITSELF?

If it's a HW100, you have most likely smashed the sears. If you have undertaken any work to the gun, ie. replaced the anti tamper, when re-assembling you MUST make sure that the trigger unit is NOT in a cocked state (press the trigger before attaching to the gun). If you fit the trigger section to the gun when it is cocked you WILL smash the trigger sears - usually the middle sear.

If it's a HW110, the sears are probably worn, they are not a great design on the HW110, they tend to wear out faster on the HW110 compared to the HW100.

How do you know if you have damaged sears? On cocking the gun, when you push the cocking lever forward, the gun automatically fires itself (this is because the sear adges are smashed and there is nothing for it to "latch" to).

Weihrauch HW100 with a chipped middle sear

HW100 - What is leaking, the gun or the air cylinder?

The easiest way to determine whether it's your gun OR theWeihrauch air cylinder that is leaking on your HW100 is to take the air cylinder off the gun, put some air into it, pop a balloon over each end of the cylinder, making sure that you cover the fill port and the gap where the end cap is screwed onto the tube (see picture). Check that the balloons do not have any tiny holes in them, leave it for a few hours and if either of the balloons inflate, you know that it's your air cylinder that is leaking, and you also know which end is leaking! If it doesn't inflate - you have a leak on your gun. The first seal to replace is the 2665d - the one that you can see inside the block where you screw your cylinder in. Be careful taking the old seal off - don't scratch the brass valve! If it's still leaking after that, try a full service seal kit - or send it to us!

Detecting a leak on the Weihrauch HW100 Air Cylinder

HW100 - REPLACING THE 2665D SEAL on the brass valve

The 2665D seal (the little seal you can see sitting on the brass valve inside the block when you unscrew the air cylinder) is considered a consummable on the HW100 - this is usually the first seal that needs replacing, particularly if you are taking the air cylinder on and off the gun. PLEASE be very careful when removing the old seal from the brass valve - more often than not, we see scratches/gouges on the sealing face of the valve when guns come to us for service because someone has used something sharp/metal to remove the old seal. Once you scratch this surface, you will most likely find that the gun develops a slow leak - it only has to be a small scratch, but 200bar will find a way to get through it! CLICK HERE to buy replacement seals for your HW100.

Scratches on the sealing face of the Regulator Valve

Checking for a Leak

PLEASE don't put your gun in water! That goes for the cylinder also... the cylinder ends may look like they are sealed, but the glass covering on the gauge end is just that, a covering. If you suspect a leak on your air cylinder, put a bit of air in it, take it off the gun & put a balloon over each end of the cylinder, make sure you cover the fill probe hole with the balloon and leave it for a few hours - if either of the balloons inflate, even slightly, you have a leak.

Learn More

We have found that this leak detection fluid from B&Q (UK) is really handy stuff for your gun:-

Checking to see if the breech seal has blown

Is your gun louder, inaccurate? If you use a pull through barrel cleaner whilst the barrel is on the gun, it CAN sometimes pull the breech seal out. Pull the cocking arm out, shine a light down the breech and you should be able to see the breech seal (or not if it's blown through the barrel).

HW100 - Air Leaking Down the Barrel?

Re-assembled the regulator block and now have a air leak down the barrel? The leak could be caused by low cylinder pressure if you fill your cylinder slowly or fit an empty air cylinder - the fix is to quickly introduce around 40 BAR into the cylinder. Because the valve spring alone does not apply sufficient pressure to complete the seal, it is aided by the regulated air pressure behind the exhaust valve. Also, be aware that some dive cylinders have restrictors already fitted into them that make the filling very slow. If this is the case, borrow someone elses cylinder, it really does work! WARNING: If you have an after-market aluminium cylinder, please be aware that it is not recommended that you fill it quickly due to safety reasons.

Learn More

This video shows how to fix an air leak down the barrel by polishing the exhaust valve housing insert and then re-seating the exhaust valve to the newly polished cover.

HW100 - WHAT'S THIS "WASHER" NEAR THE BRASS REGULATOR VALVE?

You've got a leak on your Weihrauch HW100, it's coming from a small hole under the block, you are replacing the seals around the regulator and you come across this hard, plastic washer/ring. It's not on the schematic/exploded washer, you have looked for a replacement part and it's not in the service kit... what is it, what's the part number, where can I get one from? It's not a washer! It might look & feel like a brittle, plastic washer, but once upon a time, that "washer" was a rubber oring. Over time, the orings get compressed as they are under pressure and they become hard and brittle - and that's when they start leaking as there is no "squidge" left in the rubber. Remove the old seal - be careful not to scratch anything when removing the old seal, they can be stuck in place quite hard. Replace with seal number 2674B - Inlet Valve B.

Hardened Inlet Valve B Oring in a HW100

HW100 - Regulator Slow to Fill with Air?

In short - you have probably tightened the two parts of the brass valve together too hard. It is a bit fiddly - it needs to be tight enough that the two parts do not come apart when you screw/unscrew the air cylinder in & out of the block, but not so tight that it causes the oring inside the valve to bulge. If you need to, use a small amount of blue (medium) thread-locker.

The brass valve where the air cylinder is connected directly into the gun block is not actually the main valve for the air access from the cylinder as many believe - that is inside the actual air cylinder. The nipple on the brass valve that you can see in the block simply pushes open the valve inside the air cylinder when the cylinder is screwed on. The brass valve is actually the Regulator Valve and when working properly on a HW100, should fill more or less instantly. The valve can be rebuilt but it is a lot more difficult than people expect....

The brass Regulator Valve is in two parts with an o-ring, ball bearing and spring in between them. This o-ring (in conjunction with the ball bearing) is the valve for the regulator AND the seal for the two brass parts. See ipctures below.

Most people tighten these two parts of the valve together as hard as they can. Tightening too hard can cause the internal o-ring to bulge (inwards) and slightly grip the piston pin of the regulator. This causes slow filling and fluctuations in the firing cycle.

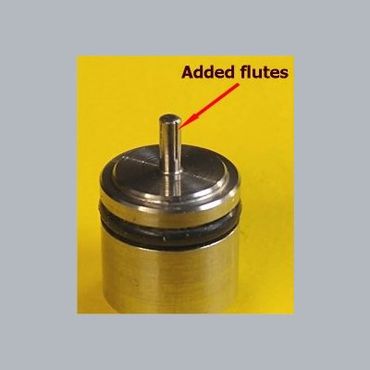

Weihrauch are presumably aware of this problem - the newer HW100's (like the HW100BP) now have a slightly different piston with a fluted pin with grooves in it to allow air through to the regulator (see 3rd picture below). Unfortunately, you can't buy these pistons yet, we are just seeing them in the newer models coming from Weihrauch!

But why would slow filling cause a problem? The plenum on the HW100 is very small and as such cannot supply enough air to fire a full shot on it's own. So when every shot is taken, some air is actually dragged through the regulator direct from the tube... but if you have a slow filling regulator, then the air flow is restricted.

Learn More

Our Brass Valve Service Kit supplies everything you need to re-build and service the brass Regulator Valve on your HW100 without having to buy the whole brass valve - saving you £££'s! We supply original Weihrauch specification seals (black) AND upgraded polyurethane seals (red) - you can use whichever ones you prefer.

JSB Pellet Label Explained

On the back of the tin of JSB pellets you will find a sticker with three sets of numbers (JSB Exact Jumbo Cal .22 pictured):

1st Number: 15050017

2nd Number: 1

3rd Number: 5.52

The 1st number is broken down into the following:

- 15 = The number of the pressing die that was used to make the pellets.

- 05 = Production Employee ID.

- 00 = Quality Control Employee ID.

- 17 = Year of production.

When buying pellets, look at the last 2 digits for the year of production - try and get the newest pellets you can - JSB had a "bad batch" in approx 2015 where the domes on the pellets were not as full as they should be and gave very poor results.

The 2nd number (1) is the manufacturing batch number.

The 3rd number is the calibre head size 5.52.

Copyright © HW100TUNING - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data. Privacy Policy